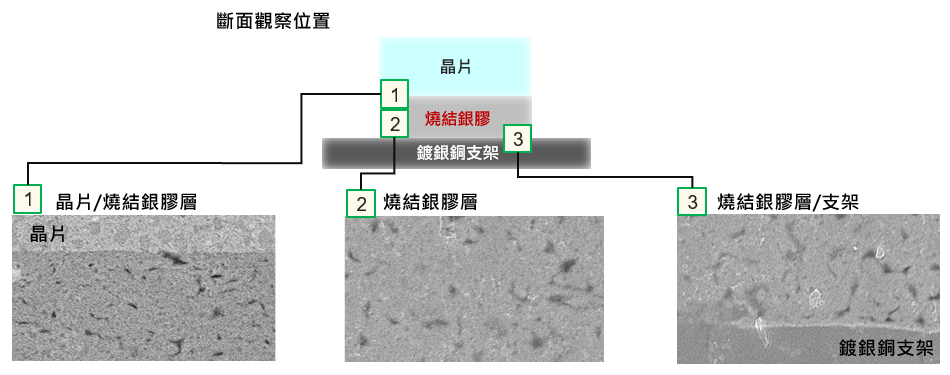

◆ Semi-sintered

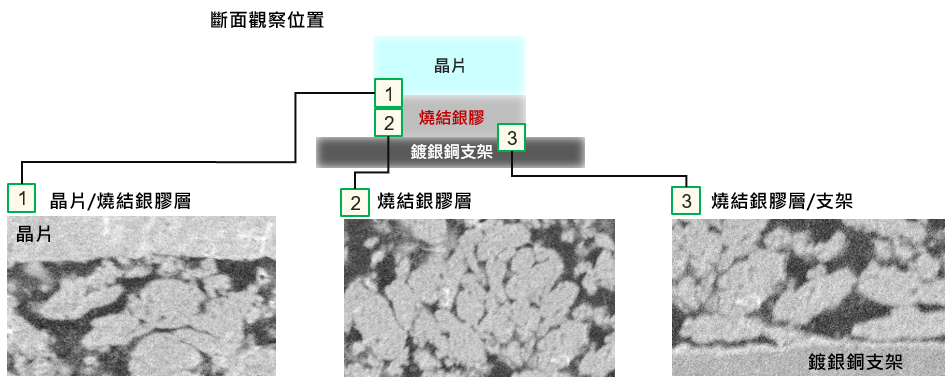

Nano-Scale Fully Sintered Die-Attach Silver Paste – FP-6100-HP9

Suitable for semiconductor packaging designs requiring high electrical and thermal conductivity. To achieve optimal performance, the die and substrate surfaces must be gold- or silver-plated. This resin-free formulation enables pure metallic bonding, significantly enhancing thermal dissipation.

Applications:

High-power packaging products

Packaging for high-temperature operating environments

SiP / QFN / LGA / HBLED

Features:

Excellent high-temperature shear strength; outstanding electrical conductivity

Compatible with adhesive stamping and dispensing processes

Superior thermal conductivity

Low-temperature sintering capability (180–200 °C)